Hooke's Law

Summary

⇒ Materials can be characterised by the properties they show when forces are applied to them

- Different materials will exhibit very different properties

- When scientists are testing materials they may apply compressive forces or tensile forces

- Compressive forces are forces that tend to squeeze an object and reduce its size in the direction that the force is applied

- Tensile forces are forces that act to pull or stretch an object

⇒ In 1678, Robert Hooke wrote about his discovery of elasticity

- He used his investigations into spring to develop a spring for use in the first portable timepiece, or a watch as they are now known

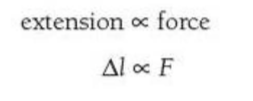

⇒ Hooke realised that the extension of some springs shows a linear region gor a range of applied forces

- In other words, the extension was proportional to the force applied

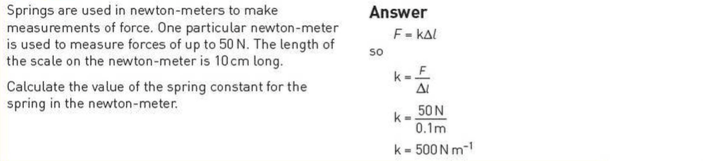

The Spring Constant

⇒ How mich a spring extends will also depend on the spring constant of the spring

- The spring constant is a measure of how easy/hard it is to stretch a spring when a force is applied

⇒ A spring that extends a large amoung for a force of 1N is not as stiff as a spring that extends only a small amount for the same force

⇒ The spring constant, k, defines the stiffness of a spring as the force required for a unit extension of the spring

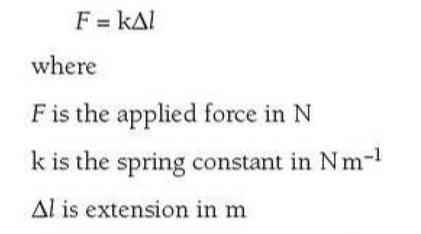

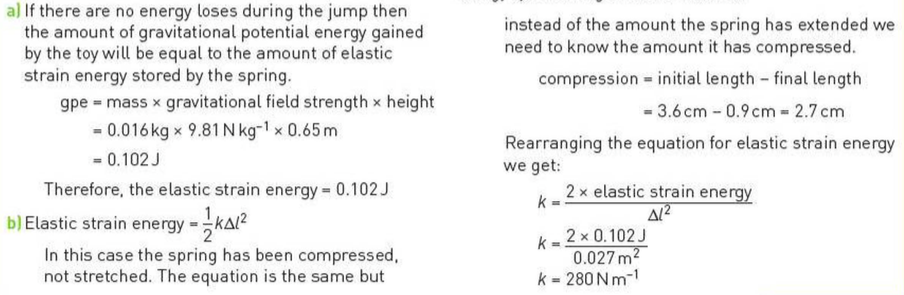

⇒ Using the simple equipment shown below, the spring constant of a spring can be measured

- The spring is stretched using a tensile load

- This is done by adding masses to a mass hanger

- The extension of the spring is measured by noting the change in the position of the pointer against the rule

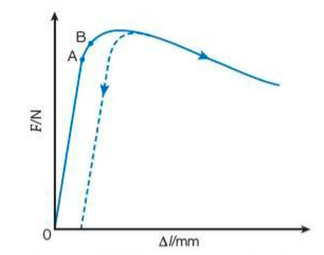

⇒ When the results from the experiment are plotted, the graph initially has a linear region, as seen above

⇒ Here the spring is still coiled and the extension is directly proportional to the load

- When more masses are added, the spring starts to stretch more for each increase of load: the extension is no longer proportional to the load

- The pint at which this occurs is called the limit of proportionality

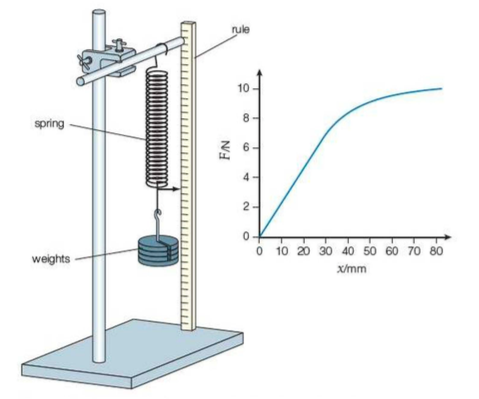

⇒ The elastic limit of a material is the point below which the spring will return to its original length when the load is removed

⇒ The spring on the left is showing elastic deformation - above the elastic limit, the spring will be stretched out of shape and will not return to its original length

⇒ This is known as plastic deformation

Example

Springs in Series and in Parallel

⇒ If you want to learn about how to calculate the spring constant with springs in series and parallel, I highly recommend this video:

Investigating wires and fibres

⇒ Nearly all materials show Hooke's law behaviour up to a point

- This includes metals such as copper and steel, fibres such as cotton and silk, natural rubbers and polymers

⇒ The applied force beyond which materials no longer obey Hooke's law will be different for each material

- In a school laboratory it is possible to investigate the properties of materials such as copper wire and nylon thread

- These materials produce measurable extensions for an easily obtainable range of applied forces

- Other materials, such as steel wire, require much larger forcs and so specialist equipment is required

⇒ Wires obey Hooke's law because the bonds between the metal atoms act like springs

- When the wire is stretched the bonds lengthen slightly. When the force is removed, the bondsreturn to their original length

- However, if the force applied is too great, and the elastic limit exceeded, then the metal atoms will be able to move past one another and the wire lengthens

- This is known as ductility, and is a very useful property as it allows metals to be formed into thin wires - ductile behaviour is an example of plastic deformation

⇒ The dotted line on this graph represents the extension measured once the force is removed from the loaded wire

- It can be seen that the wire has permanently lengthened because, even with no applied force, there is still a measurable extension

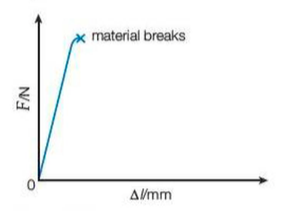

⇒ Some materials do not show plastic behaviour but are brittle and break when the elastic limit is exceeded

- Cast iron and glass are two examples of brittle materials

- The following graph shows a typical force-extension graph for high-carbon steel, which is also a brittle material

- The material fractures and breaks; it does not show plastic behaviour

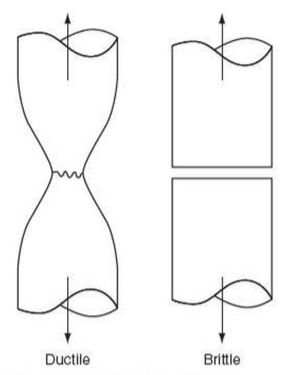

⇒ The way in which ductile and brittle materials fracture is also different

- In a ductile material, the sample of material will elongate and 'neck' before it breaks - on a force-extension graph, necking occurs in the plastic region of the graph

- In a brittle material there is no change in the shape of the material because it does not undergo plastic behaviour - a straight break in the material is seen

- The below image shows the differnce between the two types of fracture

Elastic Strain Energy

⇒ The exercise equipment shown here makes use of springs

- When you pull the two handles apart you increase the energy stored by the springs

- We can calculate how much energy is stored as elastic strain energy in the springs

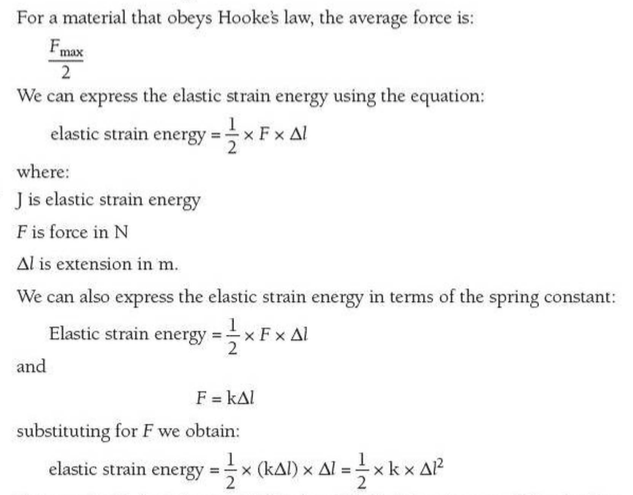

⇒ The energy stored is eequal to the work done stretching the strings

⇒ The work done depends on the average force appliedand the extension of the springs: Work done = average force x extension

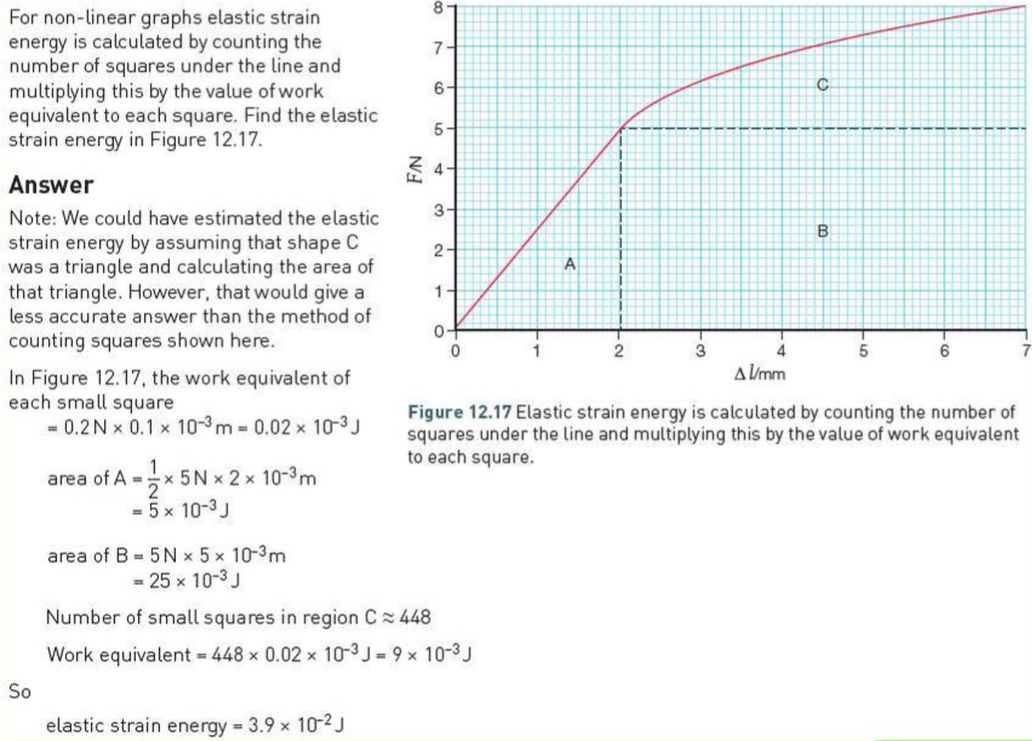

⇒ For a material that does not fully obey Hooke's law, we can still calculate the elastic strain energy by calcuilating the are under the load-extension graph

⇒ For any graph, we can choose small echanges in the extension, δl, and calculate the work done by the load to produce that small extension. The total work done is then the sum of all these values:

- WT = ΣFδl

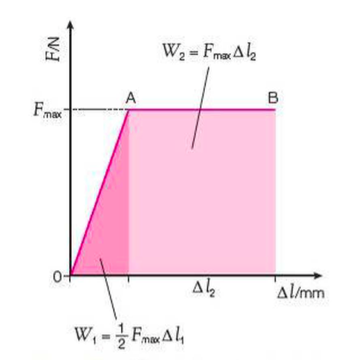

⇒ This shows how this is doene for a simplified force-extension graph

- The region marked as OA represents the applied loads for which the material obeys Hooke's law

- For this region the ara under the graph is a triangle, so: W1 = 1/2 Fmax ▵l1

⇒ For the second region of the graph, AB, the material no longer obey's Hooke's law

⇒ However, energy is still required to stretch the material, so work is still being done

- The are of this region is that of the rectangle below the line: W2 = Fmax ▵l2

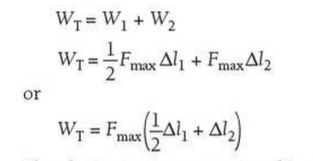

- Which means that the total work done in stretching this material is:

⇒ The elastic strain energy stored is equivalent to the work done in stretching the material

Energy and Springs

⇒ When a material is stretched or compressed its elastic strain energy is altered

⇒ Below shows two common toys that make use of stored elastic strain energy...

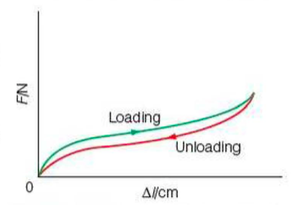

The spring jumper toy is compressed by pushing the suction cup on to the stand. When the suction cup releases the toy 'jumps' to a height of 65cm. The toy has a mass of 16g. The spring is originally 3.6cm long, and is compressed to 0.9cm long.

Assuming that no energy is dissipated as heat and sound when the toy jumps, calculate:

- A) The elastic strain energy stored by the spring

- B) The spring constant of the spring

Rubber

⇒ The classic properties of some materials, such as rubber, can be complex

- When a rubber band is stretched it will return to its original length

- However, the way in which it does this is very differnt from a metal wire

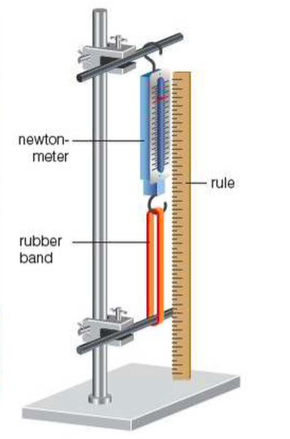

- Below shows an experimental set-up that can be used to carry out this measurement

- And this shows a typical force-extension curve obtained from this experiment

⇒ Initially, there is only a small amount of extension as the force is applied

⇒ Then, as more force is applied, the rubber band stretches easily

⇒ Finally, just before it breaks (which isn't shown in the graph) it becomes harder to stretch again

- If you have ever blown up a balloon, you will be familiar with this changing behaviour

- Initially, balloons are hard to inflate, but become much easier once you've blown some air inside

- Just before they burst, it becomes more difficult to inflate them further

⇒ The graph also shows that the extension for a given force is different when the rubber band is being loaded (top curve) or unloaded (bottom curve)

- This means that the strain energy stored when the rubber band is being loaded is greater than the strain energy released when the rubber band is being unloaded

- However, the law of energy conservation states that energy cannot be created or destroyed in a closed system

- The difference in energy strain energy must be accounted for - in this case, it will become warm as it is stretched and relaxed. This is why there is a difference between loading and unloading

Extra

⇒ Also see our notes on: